GRAPHALLOY®

10 Years and Counting in Windbox Dampers

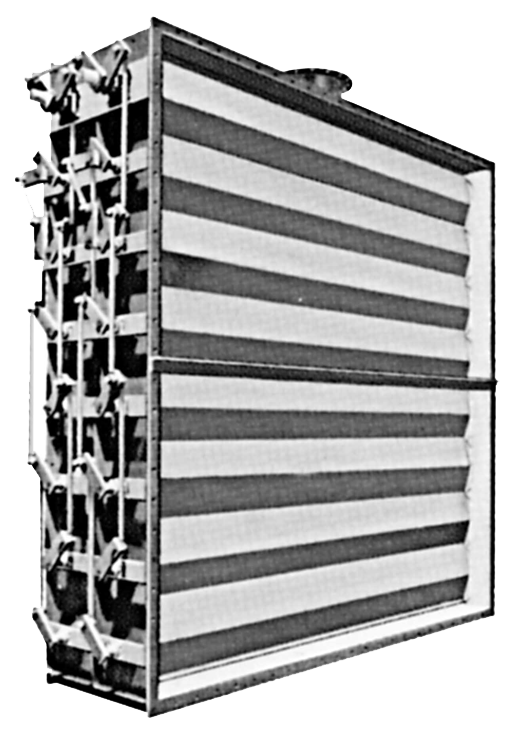

Windbox dampers are a tough environment for bearings. The dampers require bearings for the shafts that can operate at

elevated temperatures and provide self-lubrication and self-alignment. The hot air quickly dries out the lubricant in the ball bearings, causing the dampers to seize.

Misalignment occurs on many overheated and distorted windboxes. Windbox dampers are a tough environment for bearings. The dampers require bearings for the shafts that can operate at

elevated temperatures and provide self-lubrication and self-alignment. The hot air quickly dries out the lubricant in the ball bearings, causing the dampers to seize.

Misalignment occurs on many overheated and distorted windboxes.

This customer wanted to standardize their flange blocks at the beginning of their

thrust into manufacturing windboxes. The customer needed four bolt flange mount assemblies that could

handle temperatures up to 800°F and provide self-alignment capability.

The 845F4 GRAPHALLOY assembly was very similar to the assemblies that they had preliminarily selected. Their engineers were

reluctant to change, as they did not understand our self-aligning

assembly. Drawings were faxed and samples of an 845F4 assembly were

sent for them to examine. They liked our self-aligning method and the

material’s capability to 1000°F.

The customer has standardized on the GRAPHALLOY 845F4 with 1" shaft and changed their

drawings accordingly. They have experienced 10 years and counting without failures. The customer has standardized on the GRAPHALLOY 845F4 with 1" shaft and changed their

drawings accordingly. They have experienced 10 years and counting without failures.

Why Graphalloy?

GRAPHALLOY provides unique advantages because it combines the properties of graphite and metal. The graphite structure can be compared to a deck of cards with individual layers that are able to easily slide off the deck. This phenomenon gives the material a self-lubricating ability that is matched by no other material. External lubricants are simply not necessary. The material continues to work at temperature extremes. It is available as cylindrical bushings, split and metal backed bushings, as well as pillow block and flange units. Grades and designs are engineered to best serve the application.

|