GRAPHALLOY® Upgrade

Tames Problem Pentane Pumps

In October 2014, we received an email from the Rotating Equipment Reliability Engineer at a major refinery in California:

“I am one of the machinery engineers at this refinery. I believe I met you briefly during your recent visit to our site.

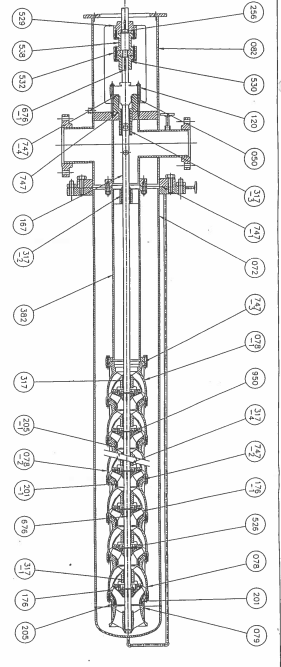

I have a BW/IP VLTF 19 stage deep-well vertical can pump that I would like for you to quote for a Graphalloy installation. The pump is currently apart in our onsite machine shop.

The pump previously had [Teflon® PFA and carbon fibers composite bushings] installed, but during a recent event, the Teflon binder was removed from the carbon-fiber matrix and all of the carbon fiber “unraveled” and migrated downstream, clogging the pump.

The service is pentane at 275-300°F with occasional “light cycle oil” (i.e. “LCO”) washes at possibly higher temperatures (400-500°F).

I have cc’d our Machine Shop Foreman who could provide dimensional information for the impeller hub/eye wear stationary rings and line bushings for the application.”

Our engineers worked with the Foreman and his team to design-in GRAPHALLOY Nickel-grade bushings and wear rings which were installed in the pump a few days later. Self-lubricating Nickel-grade GRAPHALLOY operates in temperatures from

-400°F to 750°F and can easily handle low lubricity fluids and caustics. After one year of successful service, they upgraded the sister pump with GRAPHALLOY.

We met with the Rotating Equipment Reliability Team Lead in October 2019 and he told us that “the pumps upgraded over 5 years ago are still working great.” He also elaborated on the failure of the composite bearing materials previously used: “the [composite bushings] failed in these 19-stage pumps because we add a cutter (solvent) to the pumpage and it made the [composite bushings] unravel and clog the pump.”

These pumps are still in operation today, with the original GRAPHALLOY bushings installed. In addition, they have upgraded many additional pumps at this refinery, over the past few years, with the Graphalloy Solution.

|