GRAPHALLOY® For High Temperature Glass Plant Bearing Applications

Background

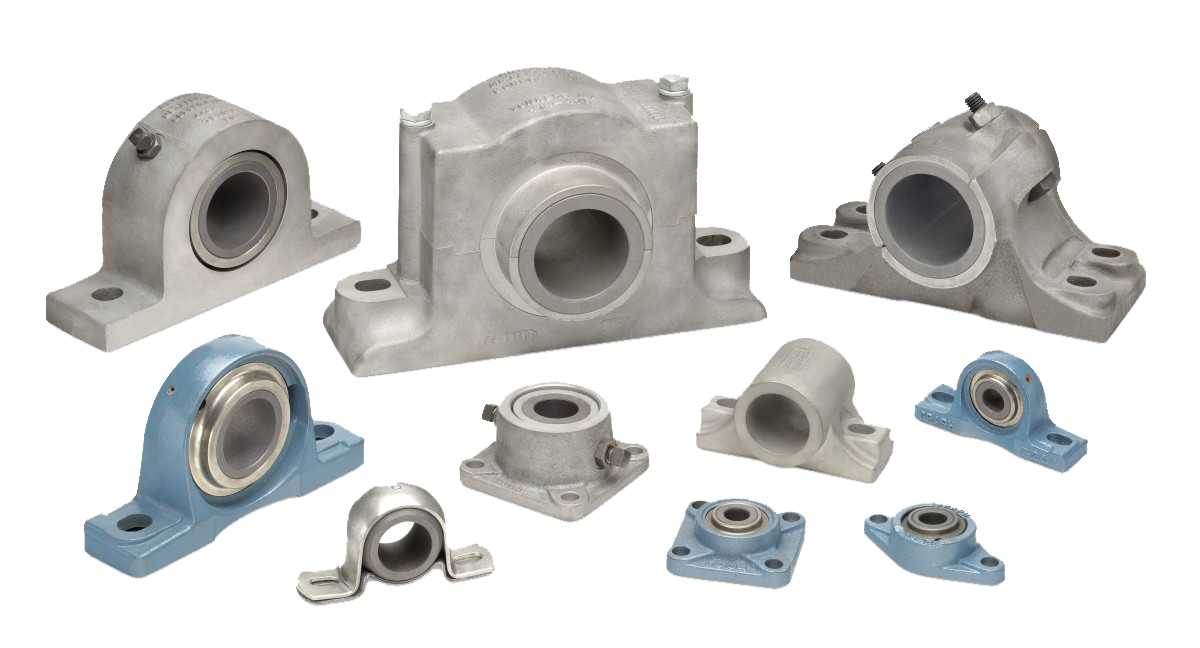

GRAPHALLOY® is ideally suited for tough glass plant bearing applications. This material eliminates the need for grease and other lubricants and can operate in high temperatures.

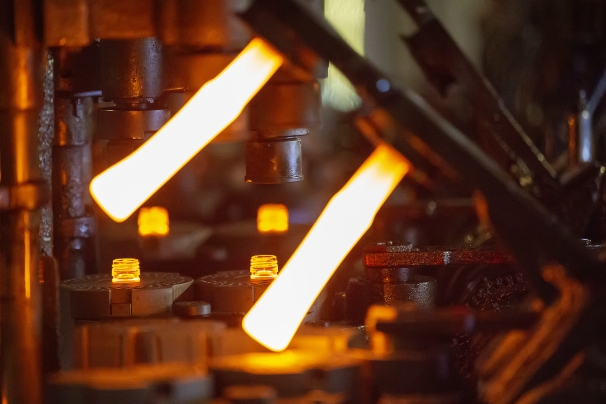

GRAPHALLOY, a graphite/metal alloy, is formed from molten metal, graphite and carbon. It is a uniform, solid, self-lubricating bushing and bearing material. It is corrosion resistant and does not collect dust or contaminants. It can operate in temperatures up to 1000°F.

Benefits

GRAPHALLOY bearings require minimal maintenance and can reduce downtime, resulting in uninterrupted production of glass products. With a low coefficient of friction and high strength, GRAPHALLOY bearings deliver long life and are not subject to seizures, binding or sudden failure.

Applications in Glass Plants

Graphalloy bearings for glass plants

Graphalloy bearings have been successful in the following applications:

- Rolls on Washing Equipment

- Forming Rolls

- Furnace Charger Plate Rollers

- Conveyors on Bottle-Heat Treating Lines

- Drive Mechanisms for Float Glass

- Light Bulb Manufacturing

- Lehr Bearings

Do you have a problem glass application? If so, chat with us now or email us at sales@graphalloy.com

Graphalloy Success Stories in Glass Plant Applications

Graphalloy Cam Followers last 4x longer in high temp conveyor application:

A glass cook top manufacturer was using conventional cam followers to transport molten parts on a conveyor through a curing area. Unfortunately, these cam followers were seizing up as frequently as every two weeks due to the high temperatures involved — 650°F or more. After GRAPHALLOY cam followers were installed, the useful life of the component was extended by more than 4X compared to the original cam followers. Estimated maintenance cost savings to date has now exceeded $15,000 per year.

Graphalloy bushings extend useful life from 6 months to more than 4 years

A windshield manufacturer was experiencing catastrophic bushing failures every 6 months — and sometimes more often — in their high temperature ovens. The bronze bushings they were using were expected to operate at temperatures of 800°F or more. Since the plant needed to produce 3500 windshields a day, any lost production due to down time was tremendously expensive. After GRAPHALLOY bushings replaced the bronze bushings, production lines have been operating for more than 4 years now without a single bushing related failure.

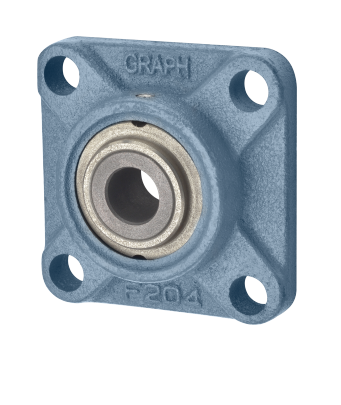

Graphalloy flange units eliminate fire hazard and reduce downtime

A custom glass manufacturer was experiencing premature failures in the rolling element bearings used in their lehrs and cross-over conveyors. The cross-over conveyors — and the conveyors running through the lehrs — are heated to 400°F to avoid checking problems (cracking) in the parts being made. To compensate for lubricant burn-out, bearings were being heavily greased. The excessive use of grease was creating a safety problem in the form of a fire hazard. Greased bearings were replaced with self-lubricating GRAPHALLOY type 845F4 4-bolt, high temperature flange units. These Graphalloy bearings eliminated the fire hazard issue and the premature failures. In the first nine months alone the company saved over $150,000 in reduced downtime, less lost production, and lower maintenance costs.