GRAPHALLOY®

Custom Babbitt-grade Bushings and Thrust Washers for North Sea Application

CUSTOMER: Pump Manufacturer, whose end customer is a major oil & gas

company in the U.K

BACKGROUND: Pump company was designing and manufacturing a small end suction pump which uses a

magnetic drive. They needed radial and axial bearings for the pump, which would be installed

in a harsh environment – an oil & gas company’s off-shore platform in the North Sea.

APPLICATION: Suction Pressure, 1.55 Bar Differential pressure, 55°C to 73°C, 0.7

to 0.73 specific gravity, 0.4 to 0.65 Cp viscosity, 3400 RPM. It is an

ATEX Zone 1, Group 2B, T3 Pump, so the temperature is monitored, and the pump is shut down

if the temperature gets higher than 73°C. The pumped media is hydrocarbon condensate.

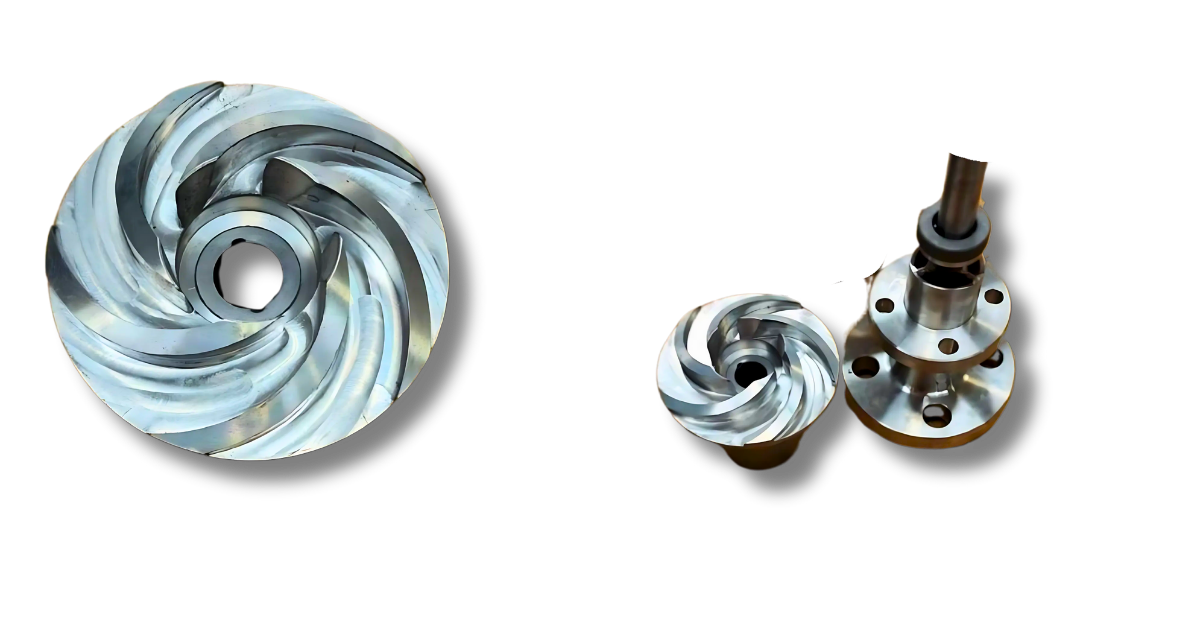

Graphalloy Solution: The pump company’s engineers worked with GRAPHALLOY engineers to design custom,

Babbitt-grade bushings and thrust washers for this unique application. The shaft is stationary

and approximately 15 mm in diameter. The Impeller and magnetic drive rotate around the

shaft on radial bearings, with a single thrust bearing required at the inlet end. There is also up

to 5 ppm of sand in the fluid, so the GRAPHALLOY engineers recommended a spiral groove in

the ID of the bushings to wash particles through the bore.

RESULTS:

The pump company engineer said “the magnetic drive pump in hydrocarbon condensate

service has been working very well, for over 8 months now, and the customer is very happy. We

are now upgrading two more of these pumps with Graphalloy. We do not foresee any

problems as we have many similar Graphalloy bearing arrangements in service in all kinds of

duties, some far more arduous than this.”

|