GRAPHALLOY® Bearings

From Frequent Failures to Four Years of Reliability in Snack Food Fryers

- Industry: Food Processing

- Application: Potato Chip Fryers

- Customer: Major Potato Chip Producer (Division of a Leading Snack Food Company)

Challenge

In their continuous fryer systems, manufactured by Heat & Control®, this producer faced recurring failures with greased ball bearings. Bearings used on belts and paddles in the fryers experienced extreme conditions:

- Exposure to 400°F

- Continuous splashing with hot oil

- Full submersion in cooking oil for certain locations

Despite regular re-greasing, the bearings on the hold-down belt had to be replaced every 3 to 4 months. Maintenance was costly, and unplanned downtime was disruptive.

Graphalloy Solution

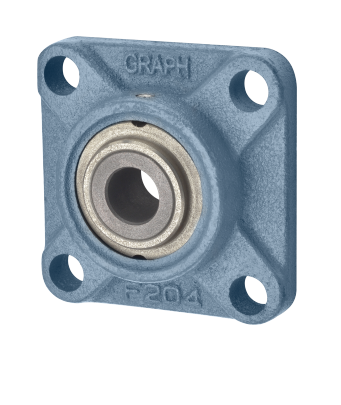

GRAPHALLOY® supplied FDA-acceptable bearing inserts that fit directly into the existing housings. Later, the producer upgraded to 845SS self-aligning 4-bolt stainless steel flange block assemblies with GRAPHALLOY inserts.

Results

- Bearings have run for over four years with no failures.

- Dramatic reduction in maintenance requirements and costs.

- Complete conversion: All fryer bearings are now GRAPHALLOY.

Conclusion

GRAPHALLOY's high-temperature, self-lubricating bearings provided a durable, grease-free solution that continues to deliver value in one of the food industry's most demanding environments.

For more information, contact us at sales@graphalloy.com.