GRAPHALLOY®

Bearings for Nuclear Power & Research Applications

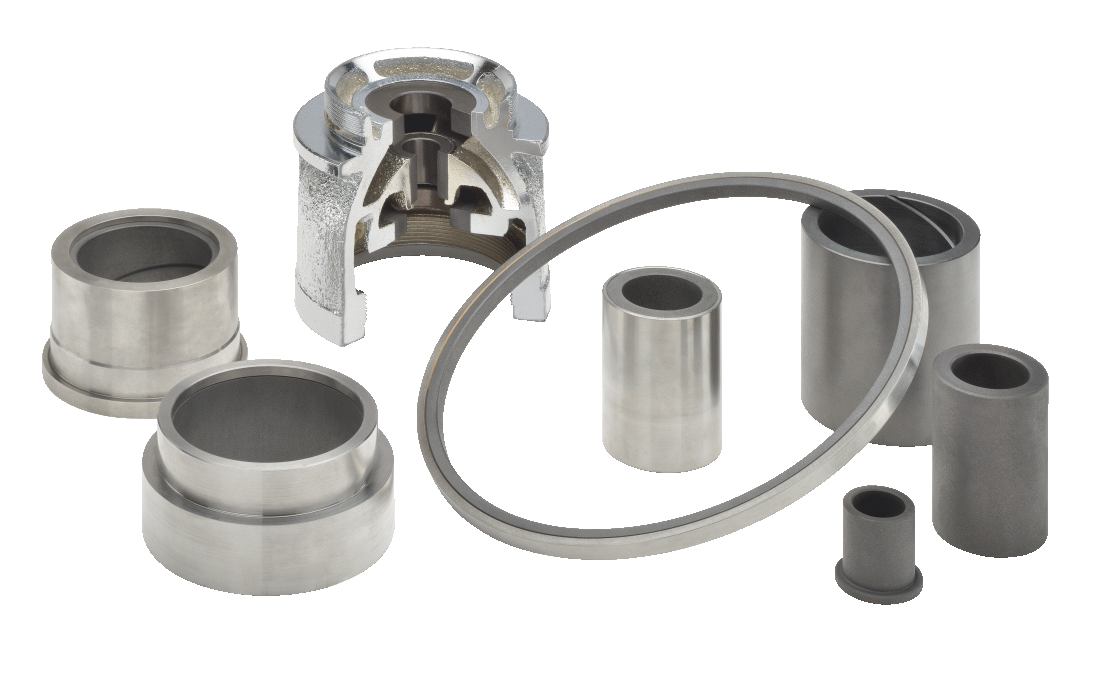

Nuclear energy demands components that never flinch—whether they face 1000°F (535°C) steam, borated water, or unplanned dry-running events. GRAPHALLOY self-lubricating bearings meet that challenge by combining the strength of metal with the lubricity of graphite. The result is a bearing that operates without oil or grease, resists corrosion, and keeps critical pumps and motion systems online for years.

Why GRAPHALLOY for Nuclear Applications

- Self-Lubricating: No oil or grease required, eliminating contamination risks

- Extreme Temperature Range: Operates from -450°F to +1000°F (-265°C to +535°C)

- Resistant to Borated Water and Nuclear Chemistries

- Non-galling: Survives Dry-Running and Loss-of-Coolant Events

- Maintenance-Free: No grease purge to manage

- Over 100 Material Grades Available for Specific Requirements

Nuclear Applications for GRAPHALLOY

- Reactor Coolant Pumps

- Spent Fuel Pool Systems

- Circulating Water Pumps

- Heater Drain Pumps

- Emergency Core Cooling Systems

- Research Reactor Equipment

Engineered for Extreme Environments

Most bearing alloys soften or seize as temperatures rise. GRAPHALLOY maintains its integrity up to 1000°F in air and even higher in inert atmospheres. In submerged reactor-pool service, the material maintains lubrication without the need for external lubricants that could contaminate the system.

Maintenance-Free by Design

Because GRAPHALLOY is self-lubricating, there is no grease purge to manage and no risk of oil leaking into safety-related systems. This eliminates a major maintenance burden and potential contamination source in nuclear facilities.

Survives the "What-If" Events

Dry runs during pump priming or loss-of-coolant transients can destroy polymer bearings or metal bearings in seconds. GRAPHALLOY's non-galling surface allows pumps to coast through these upsets unharmed, providing an extra margin of safety for critical nuclear systems.

Ready to upgrade your plant's reliability? Chat with us now, email or use our inquiry form

Proven GRAPHALLOY Applications in Nuclear Facilities

Spent Fuel Pool Pump

A nuclear power plant needed bearings for their spent fuel pool circulation pumps that could handle continuous submersion in borated water at elevated temperatures. Traditional bearings required frequent replacement due to corrosion and lubricant breakdown. GRAPHALLOY nickel-grade bushings were installed and have provided years of reliable, maintenance-free service in this demanding environment.

Circulating Water Pumps

Large circulating water pumps at a nuclear generating station were experiencing premature bearing failures. The combination of high loads, continuous operation, and potential dry-running during start-up was destroying conventional bearings. GRAPHALLOY bronze-grade bushings were specified as replacements, providing extended service life and eliminating the risk of catastrophic failure during dry-running events.

Nuclear Heater Drain Pump

A nuclear facility's heater drain pumps were experiencing frequent bearing failures due to the high-temperature condensate and intermittent dry-running conditions. The maintenance team specified GRAPHALLOY self-lubricating bushings, which can handle temperatures up to 1000°F and survive dry-running without damage. The result was significantly extended bearing life and reduced maintenance downtime.

Specify with Confidence

With more than 100 material grades, Graphite Metallizing Corporation engineers can match a bearing to virtually any nuclear water chemistry or temperature profile. Every sleeve bearing, flange block, or thrust washer is machined in Yonkers, NY under ISO 9001 quality control and shipped fully inspected.