GRAPHALLOY® High Temperature Bearings & Bushings

|

Standard |

Screw Conveyor |

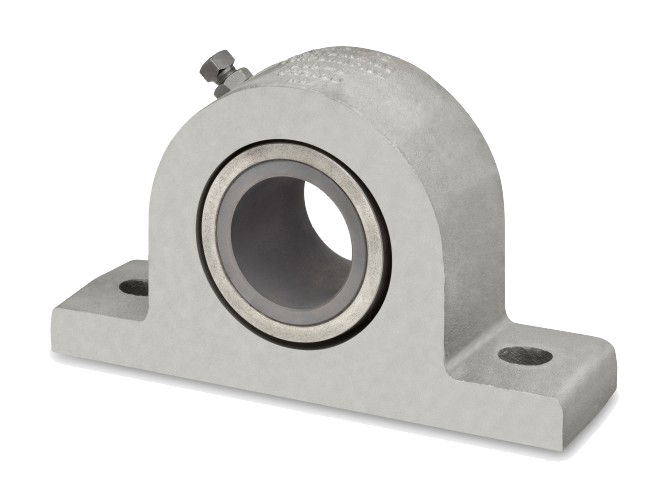

2-Bolt Pillow |

Flange Blocks |

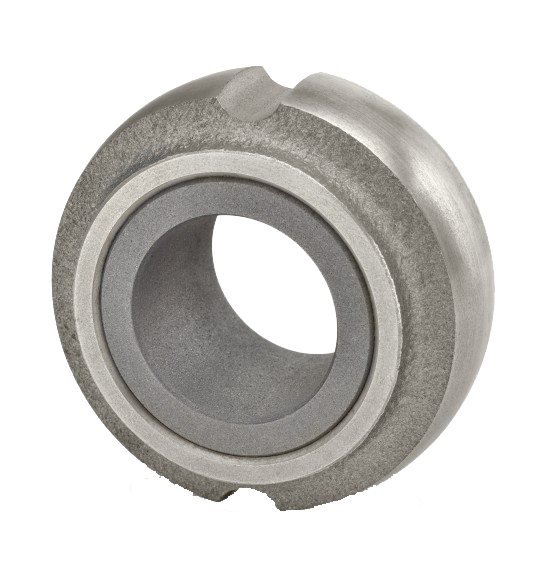

Inserts for Pillow |

|---|

GRAPHALLOY® can solve your toughest bearing problems. Let us show you how. Email Us - Chat with Us Now - Use Our Inquiry Form or follow the links below.

High temperature environments are difficult for many bearing types. Plastic bushings soften or melt, and the grease/oil lubrication in rolling element bearings or metal bushings carbonize, leading to bearing failure and equipment downtime. In these tough conditions, self-lubricating Graphalloy bearings can be the solution.

The GRAPHALLOY bushing material is a graphite-metal alloy– the graphite provides the self-lubricating quality and the metal gives it enhanced wear resistance.

Click below for examples of how GRAPHALLOY high temperature bearings have solved problems, reduced costs and downtime and increased productivity in high temperature applications:

- Cam Followers for Glass Ceramic Manufacturer

- Replacing Ball Bearings in High Temperature Oven Carts

- High Heat Spells Problems for Traditional Bearings

- Other High Temperature Bearing Solutions

Many more examples of Graphalloy high temperature bearing success stories can be found on our case histories page.

Do you have a troublesome, high temperature bearing application? If so, tell us about it by using our inquiry form and our sales engineers will contact you. Or, if you prefer to contact us directly, click here.

09/19/2022