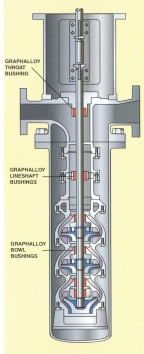

GRAPHALLOY®

Wear Parts For

Horizontal and Vertical Pump

Survival

GRAPHALLOY, a graphite/metal alloy, is a self-lubricating,

non-galling bearing material used by designers, reliability, and

maintenance engineers to solve the toughest pump application

problems. Use GRAPHALLOY for case rings and pump bushings.

GRAPHALLOY case rings and bushings allow pumps to survive repeated

"run-dry" conditions, slow roll operation, and frequent

stop/starts....conditions where metal and plastics fail. plastics fail.

GRAPHALLOY enables the pump to run dry and survive - restart or continue

operating often without loss of performance or the need to replace the

GRAPHALLOY parts. Plastics, such as PEEK, may enable a pump to run dry

briefly without a catastrophic crash, but generally a rebuild of the pump

will be required, including replacement of the thermoplastic parts.

GRAPHALLOY has a wide temperature range with pump applications from

cryogenic to 1000° F (540°

C). Maintains clearances over entire operating range.

GRAPHALLOY bushings and case rings can improve the reliability and efficiency of your pumps. In horizontal and vertical pumps, non-galling GRAPHALLOY does not seize or gall if run dry or with marginal lubrication.

The GRAPHALLOY fitted pump is able to survive upsets, dry running, loss of suction, slow roll on standby and other transient conditions that would damage a conventionally fitted pump.

Pumping low lubricity fluids, hydrocarbons, liquid gases,

or hot water can be especially difficult for a metal-on-metal pump; GRAPHALLOY solves the problem. Using GRAPHALLOY also

allows closer clearances often

gaining efficiency improvements, reduced vibration and reduced NPSH requirements.

Key Benefits:

- Permits Dry Starts and Dry Running

- Wide Temperature Range

- Survives Frequent Suction Loss and Pulsation

- Improves Efficiency

- Reduces Vibration (permits closer fits)

For more information download our

Pump Brochure or call our sales engineering staff.

Use our

Inquiry Sheet to ask about a GRAPHALLOY

solution for your application.

|  plastics fail.

plastics fail.