The Science of GRAPHALLOY®

What it's made of, what it can do for you

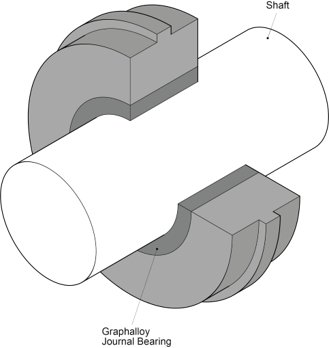

What is GRAPHALLOY®

-

BEARING MATERIAL:

A journal bearing alternative for bearings in extreme environments. Its successful uses are divided about 50/50 between:

- 1) replacements for ball bearings in hot or cold or wet environments, and

- 2) replacements for metal/plastic bushings in pumps that experience upset conditions.

- GRAPHITE + METAL: Graphalloy is a family of proprietary graphite-metal alloys developed by the Graphite Metallizing Corporation. It has been in use in industry for over 100 years and in pumps for over 70.

- SELF-LUBRICATING: Graphalloy is a uniform, solid, self-lubricating material commonly used for wear rings, bushings and bearings due to its unique properties.

- EXTREME: The material is made by combining molten metal and solid graphite at extreme temperature and pressure. The resulting product handles extreme environments, both cold and hot (-450°F to over 1000°F / -269°C to over 538°C).

How Does GRAPHALLOY® Work?

Each of the components of GRAPHALLOY play an important role:

GRAPHITE

- Hexagonally arranged carbon atoms form flat sheets, which slide off each other (like a deck of cards).

- These sheets give graphite its self-lubricating properties and classify it as one of very few “dry lubricants”.

METAL

- Adds mechanical strength where graphite is soft.

- Acts as a heat sink, helping to remove friction heat from the surface of the shaft.

- Different metals are used to achieve different properties.

How Is GRAPHALLOY® Made?

- Manufacture proprietary graphite.

- Machine to near-net size.

- Heat.

- Combine with molten metal under pressure.

- Remove and cool.

- Machine to finished size.

Let us solve your immediate problem: chat with us now, email or use our inquiry form.